GRP (Glass Reinforced Plastic) pipe seals and gaskets are essential components used in the construction and maintenance of pipelines made from composite materials, particularly GRP pipes. These seals and gaskets play a crucial role in ensuring the integrity and leak-free performance of GRP pipelines in various industries, including water and wastewater management, chemical processing, oil and gas, and more. Here, we will explore the key features, types, materials, and applications of GRP pipe seals and gaskets.

Key Features of GRP Pipe Seals and Gaskets:

- Leak Prevention: The primary function of GRP pipe seals and gaskets is to create a secure and reliable seal between pipe joints, preventing the escape of fluids or gases and minimizing the risk of environmental contamination and operational disruptions.

- Chemical Resistance: GRP pipe seals and gaskets are often manufactured from materials that exhibit excellent resistance to a wide range of chemicals, acids, and corrosive substances. This makes them suitable for use in aggressive industrial environments where chemical resistance is crucial.

- Temperature Resistance: These seals and gaskets can withstand extreme temperatures, ensuring the long-term performance and durability of GRP pipelines in varying environmental conditions.

- Mechanical Strength: They provide structural support to the pipeline joints, distributing loads and stresses evenly. This helps maintain the overall stability of the pipeline.

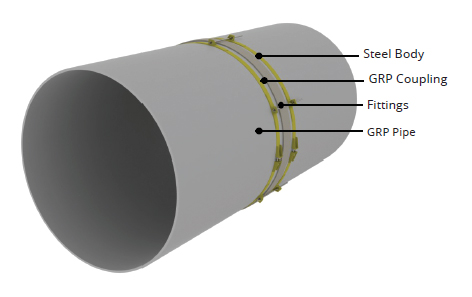

Types of GRP Pipe Seals and Gaskets:

- Compression Seals: Compression seals rely on the application of pressure to create a tight and secure seal between pipe joints. They are often used in conjunction with flanges.

- O-Ring Seals: O-rings made from elastomeric materials like EPDM, Nitrile, or Viton are commonly used to provide an effective and flexible sealing solution for GRP pipe joints.

- Lubricated Seals: Some GRP pipe seals and gaskets incorporate lubricants to reduce friction during installation, making it easier to achieve a proper seal. This lubrication also helps improve sealing performance.

Materials Used for GRP Pipe Seals and Gaskets:

- Elastomers: Elastomeric materials such as EPDM, Nitrile, Viton, and silicone rubber are popular choices due to their excellent sealing properties, flexibility, and resistance to chemicals.

- PTFE (Polytetrafluoroethylene): PTFE gaskets offer exceptional chemical resistance, low friction, and high-temperature tolerance, making them suitable for demanding applications.

- Rubber Compounds: Rubber-based compounds can provide the necessary flexibility and adaptability to accommodate various joint configurations.

Applications of GRP Pipe Seals and Gaskets:

GRP pipe seals and gaskets are used in a wide range of industries and applications, including:

- Water and wastewater treatment plants

- Chemical processing and manufacturing

- Oil and gas pipelines

- Industrial and municipal infrastructure

- Power generation facilities

- Marine and offshore structures

These seals and gaskets ensure the reliable and efficient operation of GRP pipelines in diverse environments, contributing to the safety and sustainability of various industrial processes.

In conclusion, GRP pipe seals and gaskets are indispensable components that contribute to the leak-free and efficient performance of GRP pipelines across various industries. Their choice of material, type, and installation method should align with the specific requirements and conditions of the pipeline application to ensure long-term reliability and safety.