Concrete pipe seals, also known as pipe gaskets or concrete pipe joint seals, are specialized components used in the construction and maintenance of concrete pipelines. These seals are designed to provide a watertight and secure joint between concrete pipes, ensuring that no leakage or infiltration occurs. Here’s an overview of concrete pipe seals:

Key Features:

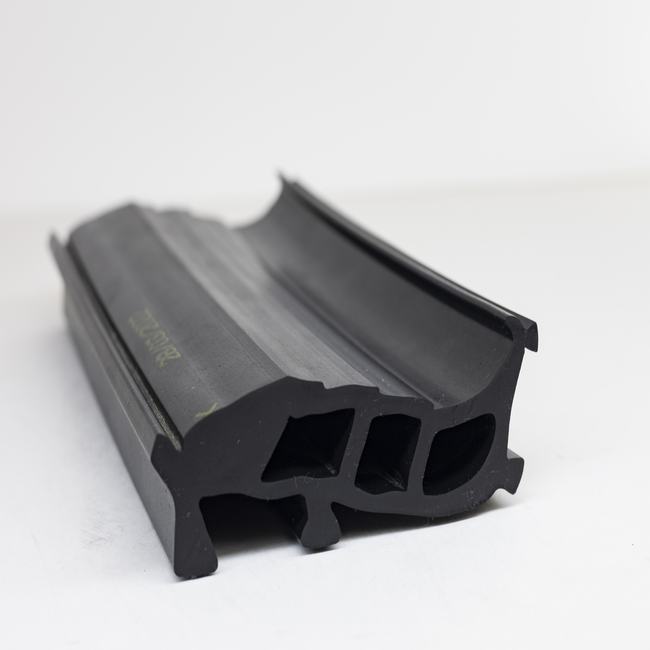

- Sealing Material: Concrete pipe seals are typically made from resilient materials such as rubber or elastomeric compounds. These materials provide flexibility and the ability to conform to irregularities in the concrete pipe surfaces.

- Compression Seals: Many concrete pipe seals use a compression mechanism to create a tight and secure seal. When the pipes are joined, the compression force is applied to the seal, causing it to expand and create a watertight barrier.

- Variety of Profiles: Concrete pipe seals come in various profiles and shapes to accommodate different joint configurations and sizes of concrete pipes. Common profiles include O-ring seals, gasket seals, and custom-designed seals.

- Chemical Resistance: Depending on the application and the specific materials used, concrete pipe seals can offer resistance to chemicals, acids, and alkalis commonly found in wastewater and industrial environments.

Applications:

Concrete pipe seals are used in a variety of applications, including:

- Sanitary Sewer Systems: They are used to create leak-free connections in sanitary sewer pipelines, preventing the infiltration of groundwater and the exfiltration of sewage.

- Stormwater Management: Concrete pipe seals are used in stormwater drainage systems to ensure that rainwater is effectively transported without leaks.

- Culverts and Bridges: In transportation infrastructure, concrete pipe seals are used in culverts and bridge abutments to provide reliable connections and prevent soil erosion.

- Industrial Pipelines: They find applications in industrial facilities for conveying various fluids, including corrosive substances, chemicals, and wastewater.

- Water Treatment Plants: Concrete pipe seals are used in water treatment facilities to maintain the integrity of water distribution and collection systems.

- Trenchless Pipe Rehabilitation: In rehabilitation and repair projects, concrete pipe seals are used to seal joints and ensure the integrity of the existing pipeline.

- Agricultural Irrigation: In agricultural settings, they are used in irrigation systems to transport water efficiently and prevent water loss.

Concrete pipe seals play a critical role in maintaining the structural and functional integrity of concrete pipelines. They are designed to withstand the pressure, movement, and environmental conditions typically encountered in these applications. Proper installation and regular inspection are essential to ensure that the seals continue to provide effective joint sealing over time.